Describe the Three Primary Interventions for Hazard Control

Identify the hazards Step 3. Primary preventionthose preventive measures that prevent the onset of illness or injury before the disease process begins.

Methods For Controlling Hazards Ufcw Safety And Health Website

FMEA hazard analysis FTA and other risk prioritization tools focus help you and your organization identify and prioritize risks.

. Describe the three primary safety programs to help management prepare for emergencies. Describe the three basic types of exposure to hazards. Hazard evaluation at the national state and local levels Implement hazard assessments as needed.

Examples include immunization and taking regular exercise. Local exhaust ventilation LEV to control risks from dust or fume is a common example as is separation of the hazard from operators by methods such as enclosing or guarding dangerous items of machineryequipment. Identifying Hazards Learning objectives in this module include.

Physical environmental and potential exposure. The steps to a hazard control process are. Acceptance and use of personal protective equipment 5.

Kill steps used prior to packaging is necessary such as cooking thoroughly or pasteurization of milk and juices. Priority should be given to measures which protect collectively over individual measures. Improvement of the public health system at the national state and local levels.

The best way to prevent biological hazards from affecting customers is to implement robust processing and storage strategies. Preventive Maintenance Systems Good preventive maintenance plays a major role in ensuring that hazard controls. Outdoor work can also create hazards from vector- borne diseases from animals and insects and poisonous plants.

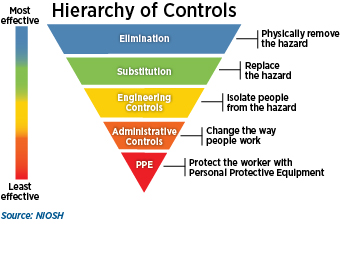

List types of work and work related activities Step 2. And help employers provide workers with safe and healthful working conditions. Elimination Elimination is the most effective method of hazard control.

Eating well exercising regularly not smoking immunization against infectious diseases. Proper use of hazard control systems in the workplace 2. Includes designs or modifications to plants equipment ventilation systems and processes that reduce the source of exposure.

Hazard identification and risk assessments are the first line of defence and hopefully the only line needed to prevent project incidents and are followed by hazard reports incident reports and incident investigations when and where required. Hazard correction information can be noted on an inspection report next to the hazard description. Legislation and enforcement to ban or control the use of hazardous products eg.

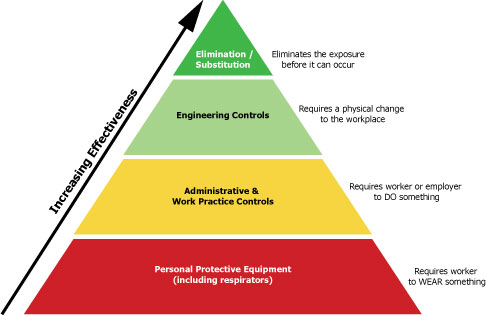

Respond to high-risk situations identify and quantify hazard-ous agents and facilitate exposure reduction. Define and give examples of hazards and exposures Describe the three basic types of OSHA-recognized hazards. Engineering controls consist of a variety of methods for minimizing hazards including process control enclosure and isolation and ventilation.

Increased awareness and recognition of workplace hazards 4. The processes described in this section will help employers prevent and control hazards identified in the previous section. Interventions can be classified into two broad categories.

Proper responses to emergency situations 8. Adherence to accepted hygiene practices 7. List and describe strategies to collect hazard control ideas.

Examples of this include using wet methods when drilling or grinding or using temperature controls. Industry employer and common sense recognition. The descriptions below provide more insight into each of the levels.

Help avoid injuries illnesses and incidents. Development of safe work habits 3. - Administrative controls which includes written operating procedures work permits and safe work practices.

Minimize or eliminate safety and health risks. Prioritize the hazards Step 4. The main ways to control a hazard include.

Asbestos or to mandate safe and healthy practices eg. Identify and implement hazard controls Step 5. Preservation of housekeeping and maintenance standards 6.

Process controls involve changing the way that a job activity is performed in order to reduce risk. Describe the three primary interventions for hazard control. List and describe the steps in Demings PDSA ycle.

- Engineering controls which includes removal or redirection of the hazard such as with local and exhaust ventilation. Reducing the probability of occurrence or the severity of the consequences of an unwanted risk say product failure is a natural outcome of risk prioritization tools. 6 proven methods for hazard identification.

Describe the three primary interventions for hazard control. Environmental hazards and health concerns. In primary prevention health promotion includes education in many forms such as nutrition and sex education.

1Engineering controls- elimination or minimizing of the hazard by designing facilities equipment to remove or process the hazardous materials or equipment. Personal protective equipment PPE NIOSH and the CDC use the pyramid below to illustrate the Hierarchy of Controls. Replace the open-topped manual skinner used for.

Counseling family planning and the promotion of physical activity are other forms of health promotion. Elimination of hazards. Use of seatbelts and bike helmets education about healthy and safe habits eg.

Secondary prevention those preventive measures that lead to early diagnosis and prompt treatment of a disease illness or injury to prevent more severe problems developing. Hazard Prevention and Control. 1 preventive interventions are those that prevent disease from occurring and thus reduce the incidence new cases of disease and 2 therapeutic interventions are those that treat mitigate or postpone the effects of disease once it is under way and thus reduce the case fatality rate or reduce the.

Remove the hazard from the workplace or substitute replace hazardous materials or machines with less hazardous ones. Most Effective Hazard Controls The best way to protect workers is to remove or eliminate the hazard from the workplace using the following hazard control methods. Substitute dangerous chemicals equipment or work methods with safer and less hazardous ones to eliminatethe hazard altogether.

Environmental protection includes sanitation air quality control and food workplace and home safety. This is one method of hazard assessment and control. Use of packaging technologies during processing like vacuum sealing hinders bacterial growth.

Describe ways to partner with OSHA to help improve the companys safety and health program. Effective controls protect workers from workplace hazards. Employee reports of hazards and reports of accident investigation should provide space for notations about hazard correction.

Chemical Hazards And Toxic Substances Controlling Exposure Occupational Safety And Health Administration

Safety Management Hazard Prevention And Control Occupational Safety And Health Administration

No comments for "Describe the Three Primary Interventions for Hazard Control"

Post a Comment